Recently, the top international journal in mechanical engineering discipline, International Journal of Machine Tools and Manufacture (IJMTM), has published the research results of Professor Wu Chuansong's group at the School of Materials Science and Engineering, Shandong University.The title of the paper is "Constitutive equation including acoustic stress work and plastic strain for modeling ultrasonic vibration assisted friction stir welding process". The first author of this paper is Zhao Wenzhen, a Ph.D student at the School of Materials Science and Engineering. The corresponding author is Prof. Wu, and Shandong University is the only completion unit.

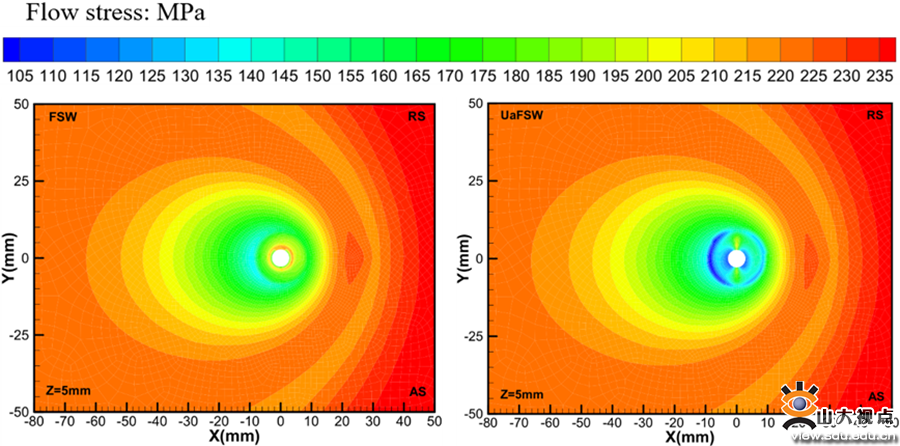

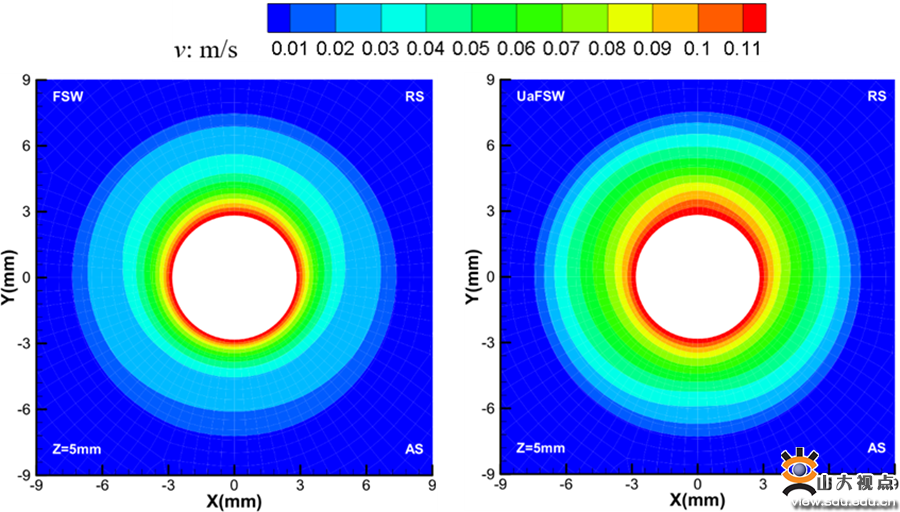

As the national economic and social sustainable development has put higher requirements for energy conservation, emission reduction and environment protection, the applications of lightweight structures design & manufacturing are increasing continuously in sectors of automobile, high-speed train, aerospace and other industries. Therefore, high-efficiency and high-quality welding of lightweight materials such as aluminum and magnesium alloys is the key problems to be solved urgently for the manufacturing of lightweight structures.To this end,Prof. Wu's research group invented a novel process variant termed as ultrasonic-assisted friction stir welding (UaFSW), which has shown excellent technological effectiveness for the welding of both aluminum and magnesium alloys.However, it needs to conduct in-depth study on the UaFSW process mechanisms.Prof. Wu's grouphas made continuous investigation in this aspect, and this paper introduced the latest results. The underlying mechanism of the synchronous interaction between the ultrasonic vibration exerted on the tool and the thermo-mechanical behaviors around the tool is analyzed quantitatively. A newmethod is put forward to modify the constitutive equations of the materials to be welded by consideringthe acoustic stress work and the acoustic softening effect. How ultrasonic vibration applied onto the tool affects the thermal-mechanical process in the shear layer around the tool is revealed, and sufficiently validated by experiments. These research results lay a sound foundation for the improvement of the welding and manufacturing of lightweight materials components.

IJMTM is world-widely recognized as a TOP Journal in the field of mechanical engineering, ranking third (TOP 3) among the total 129 SCI indexed mechanical engineering journals in the world. Its five-year impact factor is 6.565.

This research is supported by the National Natural Science Foundation and the Key R&D Program of Shandong Province.

The link of this paper::https://doi.org/10.1016/j.ijmachtools.2019.103434

Written by:Su Hao

Edited by: Che Huiqing